BESPOKE ENGINEERING SOLUTIONS

RCS is equipped to provide engineering solutions & temporary work designs to

facilitate bespoke lifting operation and Machinery Movements.

All designs & solutions are completed by our in-house structural engineer.

Tandem Lifting With

Porta Gantries

Problem:

A large mole hole served as our

delivery route to

basement levels

for numerous plant and machinery.

The positioning and size of the mole

hole brought a

unique challenge, as

no porta gantry system could

provide a sufficient safe working

load and none had

a beam span

long enough to cover the hole

and

pick

the load from the ground floor

Solution:

A scaffold bridge was designed

&

built spanning the

mole hole, with

an even distance for load-landing

and

load-picking. A 1200mm

adjustment to the porta gantry

legs

enabled use on the scaffold bridge.

This unique practical

solution saved

thousands for the client, enabling all

deliverie

s

to basement levels.

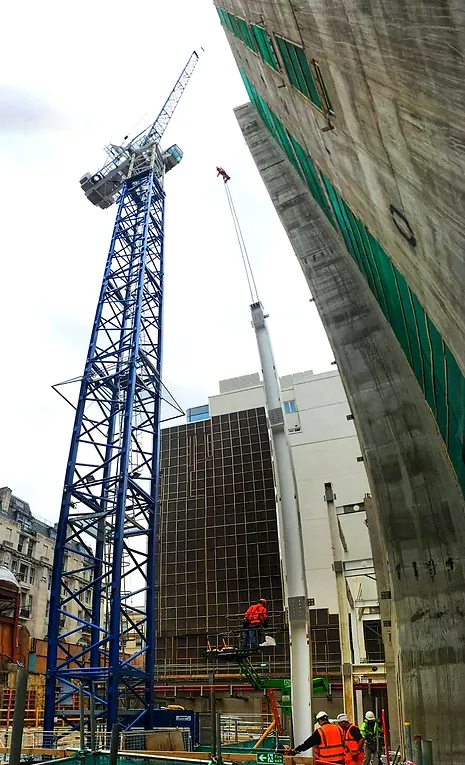

Cooling Tower

Access

Problem:

To assemble the cooling towers,

safe access on all four sides of the

towers

was critical, yet unavailable.

Solution:

Scaffolding would not suffice due

to

wind loadings, so a temporary

deck

was built over the cooling

tower

base frame using timber

sleepers.

The deck was designed to

take the

weight of a Mobile

Elevated Work

Platform (MEWP).

Landing Deck For 7

Tonne Lift Motors

Problem:

The team had to lift seven-tonne

lift

motors to level 37

& position

them

inside the lift motor room

within the

north

core. With only

tin

decking in

front of the lift motor

room

doorway,

land

the lift motors.

Solution:

A landing deck capable of

withstanding heavy point loads

was

designed & built to land and

skate

the lift motors on.

The deck

was

formed

using box-section

steel,

scaffold boards,

ply & steel

tracking

plate. The load was lifted

using site

tower cranes, landed

onto

the

temporary deck

and skated into

the

final position.

Book a Free Consultation

details of your upcoming project that

requires specialist lifting services. We will

arrange a free consultation to understand

your lifting requirements before submitting

our proposal.